Yarn sensors

Fil Control masters different kinds of technology of yarn sensors.

Expertise

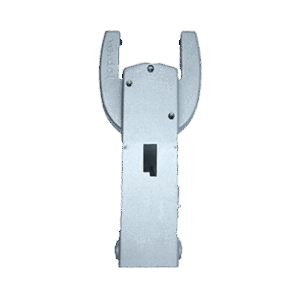

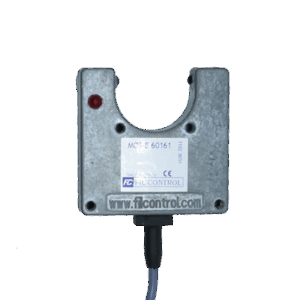

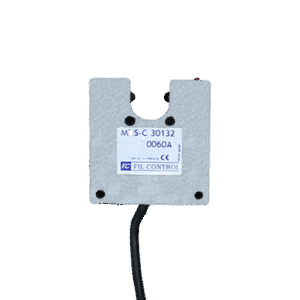

Capacitive sensors

Monitor the voltage variations produced by the electrical charges into the yarn in linear motion, even in a very harsh environment.

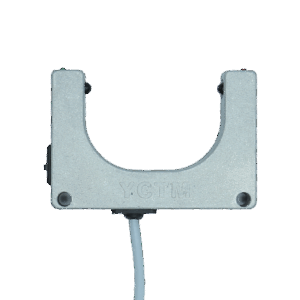

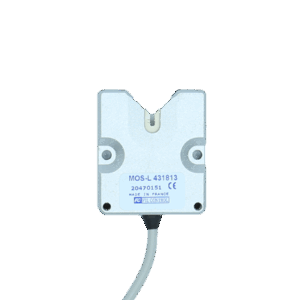

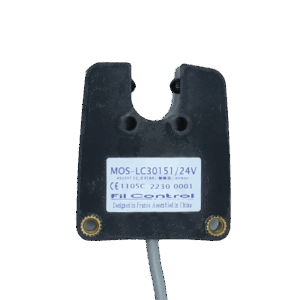

Optical sensors

Control the presence of any kind of yarn during linear, to-and-fro or ballooning motion thanks to infrared beam.

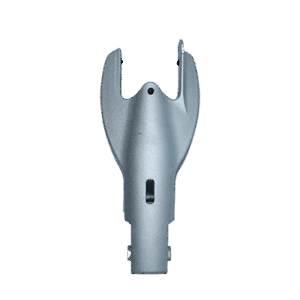

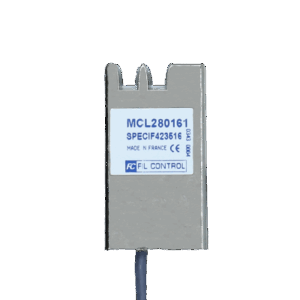

Piezo-electric sensors

Monitor a very slow motion or record yarn vibrations of the yarn sliding on ceramic. This technology uses the piezoelectric effect to measure changes in pressure, strain, or force by converting them to an electrical charge.

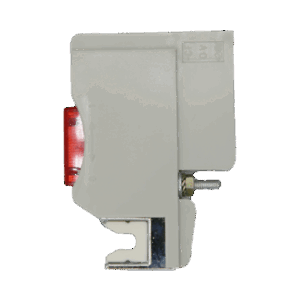

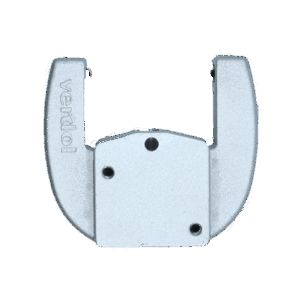

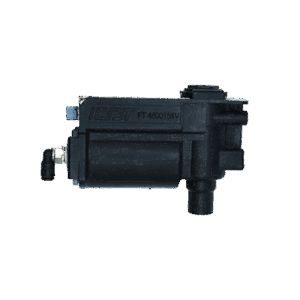

Electromechanical sensors

Detect the presence and absence of the yarn or even other parts such as yarn bobbin, at a very competitive price.

products

Our Yarn sensors

You didn’t find your product ?