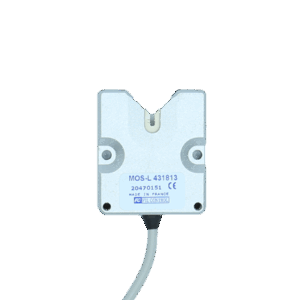

Control of the final yarn tension. MYT-T sensor deliver an analog signal proportional to yarn tension. This information will be used by machine controller to keep yarn tension constant or stop the spindle if tension is out of normal operating range. MYT-TA or TB sensor version also include a self-teaching process launched after yarn tension goes below 80g and then stay over 120g. During self-teaching process, MYT-TA or TB records tension to set a reference level. There are 2 level of windows. One for short response time (0,4s) but with wider window (±30% of reference level), and one for normal response time (2s) but with smaller window (±12% of reference level). When yarn tension goes out from predefined windows, MYT-TA or TB NPN output delivers a LOW level signal to the machine to stop position or to drive a yarn cutter.

product

| Case type | Alloys |

|---|---|

| Control System | N/A |

| Detection configuration | N/A |

| Detection head | 1 |

| Detection type | Gauge sensor |

| Fork size | N/A |

| Output type | 0-5V |

| Product type | Yarn tension sensor |

| Reload type | N/A |

| Yarn count | N/A |

| Yarn motion | Linear yarn motion |

| Yarn type | Man-made yarn Natural yarn |

| Mounting type | Screw |